Products Description

Brief Introduction

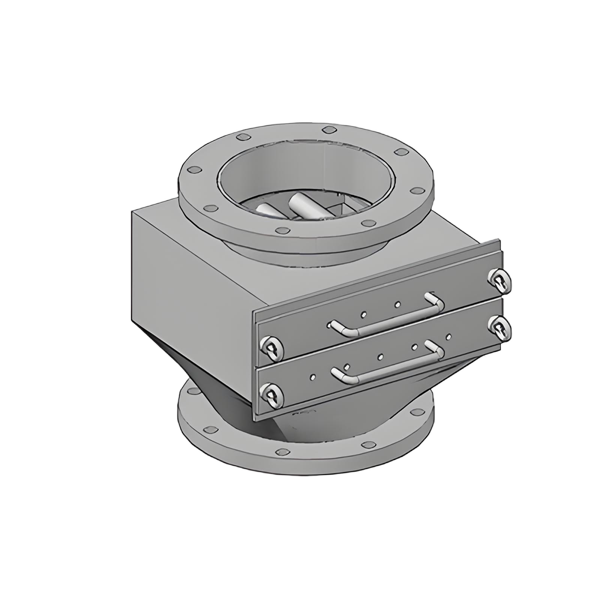

Magnetic Separators are specialized industrial devices designed to remove ferrous contaminants from various processing lines using magnetic forces. These systems employ powerful permanent magnets or electromagnets to attract and separate magnetic particles from non-magnetic materials, ensuring product purity and protecting downstream equipment.

Available in multiple configurations including plate magnets, grate magnets, drum separators, and pipeline models, these devices serve critical roles in industries where even minimal ferrous contamination can compromise product quality or damage processing machinery. The operational principle relies on creating high-intensity magnetic fields that capture ferrous particles while allowing clean materials to continue through the production process.

Features

1. Superior Contamination Control

Removes ferrous particles as small as 30 microns

Prevents product contamination in food and pharmaceutical applications

Maintains consistent product quality and purity

2. Equipment Protection

Prevents damage to crushers, grinders, and other processing machinery

Reduces maintenance costs and downtime

Extends equipment service life

3. Operational Efficiency

Continuous operation with minimal maintenance

Self-cleaning options available for automated processing

Low energy consumption compared to other separation methods

4. Versatile Applications

Suitable for dry powders, granules, and liquid slurries

Adaptable to various processing environments

Customizable magnetic strength for specific applications

5. Economic Benefits

Low operational costs with high reliability

Reduced product loss from contamination

Quick return on investment through improved quality

Application Scenarios

Food Processing Industry

Removal of metal fragments from grains, flour, and powders

Protection of processing equipment in sugar and spice production

Quality assurance in food ingredient manufacturing

Pharmaceutical Industry

API purification and quality control

Raw material inspection and processing

GMP-compliant contamination prevention

Mining and Minerals

Iron ore beneficiation and processing

Mineral purification and concentration

Recycling and waste processing

Plastics and Recycling

Metal removal from plastic flakes and pellets

Contamination control in recycling streams

Quality improvement in recycled materials

Chemical Industry

Catalyst recovery and purification

Raw material quality control

Process stream protection